The Who, What, and How of BenchForce

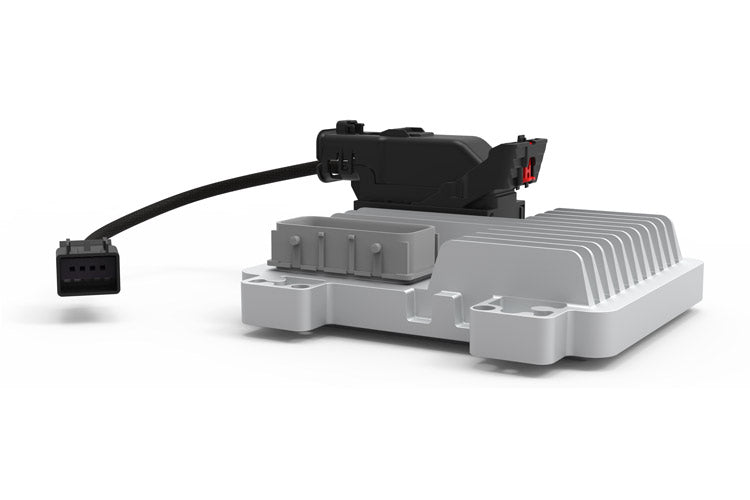

BenchForce is a company that makes a modular line of products. These products allow a technician to program parameters or edit aspects of modules that make up a vehicle's communication network. This is applicable in most cases, whether or not the module is installed in the vehicle. Working in conjunction with PowerBlock, a device that gives battery and switchable ignition (key on) power to a module when uninstalled from the vehicle, BenchForce functions as a bridge. This bridge allows you to edit nearly every module that exists in a vehicle, whether that’s a Powertrain Control Module (PCM), Body Control Module (BCM), Transmission Control Module (TCM), Electronic Brake Control Module (EBCM), and more, using your preferred interface device. The module connection path goes from the module to the BenchForce harness, then through a passthrough to the PowerBlock, ultimately linking your module to the On Board Diagnostic Port or OBD-II port.

BenchForce has a large variety of harnesses to serve common module reprograms. Do you want to reprogram a 2001 to 2006 Allison 5-speed TCM shift point table? BenchForce has a harness for that. Maybe adjust engine performance on your 2006 to 2015 GM E65 ECM that serves 2.2L, 2.4L, 2.9L, 3.5L 3.9L, 4.2L, 4.6L 5.3L, 6.0L, 6.2L, and 7.0L engines? That’s the BF01047. Let's say you just need to change the tire size in the ECM of your vehicle to clear a trouble code or fix the speedometer differential once and for all. I have one word for you: BenchForce.

Who Started BenchForce?

Mike Noonan founded BenchForce in 2018 in response to the high demand for module programming versatility. At the time, the only capabilities for reprogramming modules were to bring your vehicle into shops dedicated to tuning, which is less personal to hobbyists, or bring your vehicle back to a dealer mechanic that would drive your cost up in programming. In some cases, a typical enthusiast or hobbyist needed help to get the kind of programming they needed to improve their performance in fine detail.

Mike developed the concept of bench programming modules from a father-and-son project involving a Chevy S10. The problem was that Mike was out of state, and he needed to figure out how to program a module for the project remotely.

Mike researched his way to a solution. Being able to program a module while it is on the bench was a huge leap forward in consumer module programming. Mike's product revolutionized many industries. With BenchForce, tuning shops no longer needed to have the vehicles in-house to program them. Opening the door for “Mail-order tuning,” programming hundreds to thousands of modules per day kick-started huge revenues for tuners around the country.

The success of BenchForce is due to Mr. Noonan's initiative and helpful customer feedback. Benchforce didn't have to figure out where to go in its beginning stages because the path was laid out by the customers. Customer feedback guided Mike's research into other harnesses for standard modules until a small catalog was developed as consumer demand remained high.

Now, with the selection of almost 150 different harnesses to pinpoint your vehicle's modules, BenchForce has gone the distance with the quality of its products, producing professional-grade harnesses that will last the test of time. Each harness is made by hand, crimped, terminated, populated, and then assembled with top-tier connectors and terminals. The wires are cut with precision and handled carefully to ensure they do not fold. The communication wires are twisted consistently, and the quality control is a cut above.

What Does BenchForce’s Technology Do?

Though the process in which BenchForce develops its harnesses is quite extensive, the idea is simple; plug your module into a BenchForce harness, connect that harness to a passthrough harness, and then the passthrough harness connects to the PowerBlock. From the PowerBlock, you can connect a variety of devices such as Drew Technologies Cardaq, HPTuners MPVI, EFILive FlashScan, and any other device classified as J2534. BenchForce provides the necessary battery and ignition power requirements to activate the module into a state that can allow you to program it.

Check out this BenchForce Diagram

Without interface devices, BenchForce would not enable you to program or change anything within a module. It's simply a bridge between the module and the interface device, allowing you to do the programming you need without the module being installed in the vehicle itself. Some customers even leave the module installed in the vehicle, and simply unplug the connections to it, bypassing the old, sometimes problematic stock harness. The BenchForce PowerBlock can simulate “key on” conditions for the module to be programmed. With a toggle of the three-way switch, the “key on” is activated. Toggle this switch in the opposite direction and you have ignition + 120 ohm CAN termination.

How Does BenchForce’s Technology Help Technicians Do Their Jobs?

BenchForce finds utility in various industries, including sports, off-road, and recreational vehicle application companies and tuning outfits as well. BenchForce caters to adept hobbyists who seek to refine their vehicle programming independently. Notably, BenchForce provides an unprecedented level of accessibility to vehicles, offering capabilities that were previously unattainable.

Interact with your vehicle's modules, FAR beyond what the Original Equipment Manufacturer (OEM) would ever provide. You can touch every aspect of your vehicle's modules for any modification under the sun. Upgrade exhaust or long-tube headers. Increase airflow rates by installing turbo or superchargers, or simply a larger throttle body. Reprogram for a transmission swap or other changes to your drivetrain. You can even program for maximum power by altering your A/C compressor to switch off when needed. This means you can stock fewer Engine Control Units (ECUs) at your business by utilizing cross-compatibility between various models, simply programming the ECUs to fit the vehicle and VIN you need to program into it.

BenchForce gives you complete control over your vehicle like never before, and truth be told, probably never again with the looming shadow of OBDIII. The golden age of vehicle modification has never been as close to the typical consumer as it is today with BenchForce. The only limit is your imagination. This line of products is one of the most valuable assets a tech could have. Take it from this former Ford technician. It’s one of the greats. Snap-on, Ingersoll Rand, Mac, and BenchForce.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.